Welcome to our services page. Here you can find out more about our paint robot consulting services, the optimization of painting systems, as well as training and support.

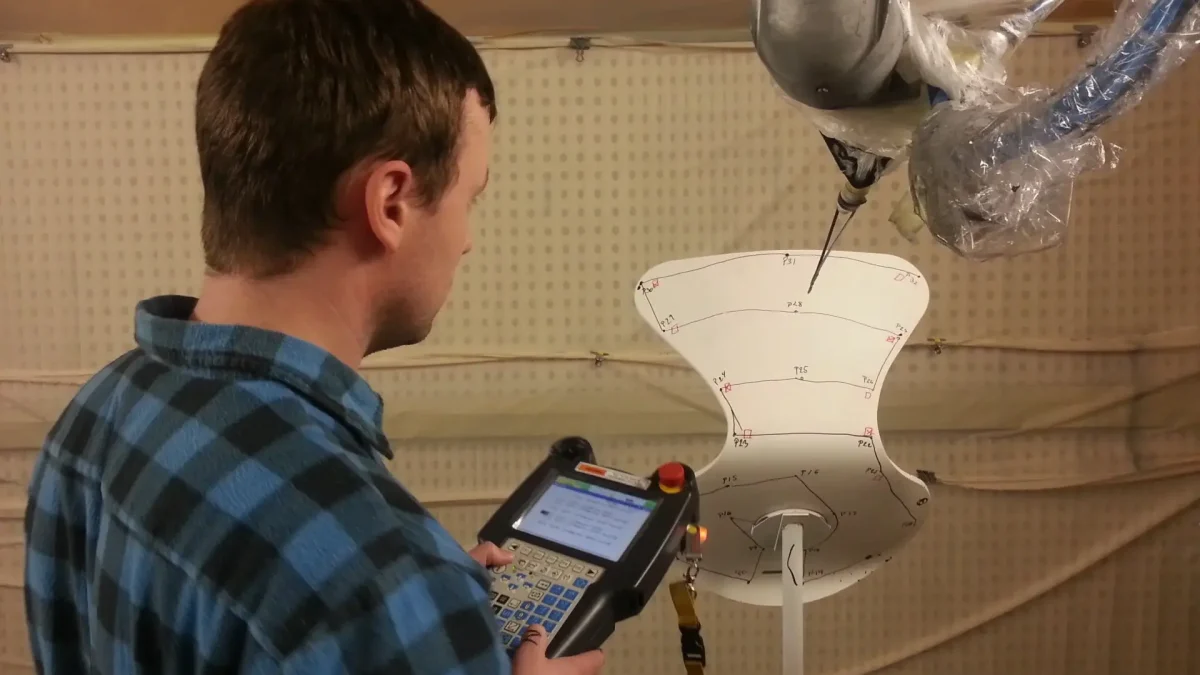

Paint Robot Programming

Many believe that programming paint robots merely involves setting up painting paths. But for us, programming means much more. The first step is precisely calibrating the applicators. Here, factors like material output rate and settings for atomizer and steering air must be coordinated to achieve 100% reproducibility—an essential prerequisite for consistently high production quality.

Next, we create spray patterns to determine optimal settings for best results. We then establish necessary subroutines such as moving to flush positions, automatic air cap cleaning, special positions, and much more. Our goal: to make the system as user-friendly as possible.

Only then does actual painting path programming begin. Here, too, you benefit from our years of experience. Precise stopping and smooth movements not only ensure outstanding quality but also minimize paint consumption.

Of course, we’ll show you how to implement all of this yourself.

Developing and Optimizing Offline Painting Programs

Through targeted planning and optimization, painting programs can be created and improved offline. This guarantees precise results—without an internet connection. Specialized software or manual input enables custom adjustments to use time and materials efficiently. Offline solutions are also particularly reliable during network issues, making them ideal for production environments. Use smart strategies to design your programs efficiently and sustainably optimize workflows.

We work closely with the Danish company INROPA, which has developed specialized software for painting applications. This allows programs to be created and optimized without interrupting the production process. Monitor the painting process on your computer and adjust it perfectly.

The crucial factor is the correct software setup to precisely match virtual painting paths with real-world results.

Assembly of Paint Robot Components

The assembly of paint robot components is a crucial step in ensuring precise and efficient operation. It involves the careful installation of all mechanical, electrical, and pneumatic parts necessary for the robot’s function. The highest level of accuracy is required to guarantee the system’s functionality and longevity. From mounting grippers and atomizers to wiring sensors and control units—each step demands expertise and precision. Professional assembly plays a vital role in minimizing downtime and maximizing the quality of painting results.

Commissioning of Robot Systems

The commissioning of robot systems is a crucial step for successfully and efficiently launching automated processes. This process includes the installation, configuration, and optimization of robot systems to ensure they function smoothly and meet the specific requirements of your applications. All components are tested, control software is adapted, and tests are carried out to identify and rectify potential sources of error at an early stage.

Whether in industry, logistics, or manufacturing – careful commissioning is essential to guarantee maximum performance, precision, and reliability of robot systems. Our experts support you from the very first step, ensuring your systems are quickly operational and can be effectively integrated. Rely on professional support to manage the entire process smoothly and efficiently.

Professional Robot Repair

Robots are an essential component of modern technology and production processes. However, even the best technology can occasionally fail. We offer you professional and expert robot repair to minimize downtime and restore full functionality to your systems. Our experienced team of specialists works precisely, quickly, and using state-of-the-art diagnostic and repair techniques. Whether it involves industrial robots, service robots, or specialized automation technologies – we guarantee a thorough analysis and a reliable solution for every problem. Rely on us for quality, efficiency, and longevity of your robots!

Robot Training and Support

In a constantly evolving world, robots and automation are becoming increasingly important. We provide comprehensive robot training to familiarize your employees with the latest technologies. Our training is hands-on and covers all essential aspects—from programming to maintenance. Additionally, we offer professional support to ensure your systems operate smoothly. Whether you’re new to robotics or already have experience, we stand by you with knowledge, expertise, and dedication to help you leverage the full potential of your robot technology.

Coating Technology

Coating technology is an indispensable component of modern manufacturing processes and plays a central role in surface refinement. Whether for protection against environmental influences, aesthetic enhancement, or improved durability – professional coating technology delivers impressive results. With advanced processes such as powder coating, wet painting, or electrostatic application, customized solutions can be implemented for a wide variety of materials and requirements. Precision, care, and the use of high-quality materials are crucial to ensuring durable and flawless surfaces. With dh surfaces-solutions as your experienced partner, you benefit not only from a first-class aesthetic and functional finish but also from a sustainable and efficient production process.

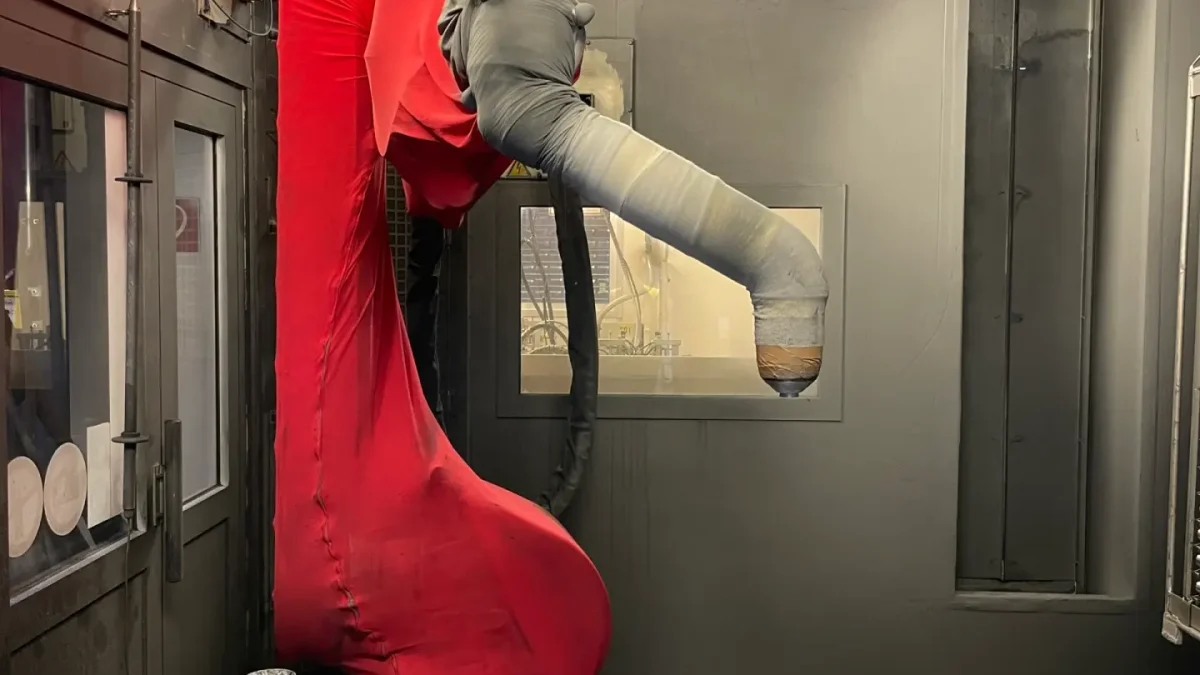

Protective Covers for Robots

Our protective covers stand for the highest standards in safety, flexibility, and quality. Specifically developed for use in explosive atmospheres, they carry ATEX certification. Their flexible design allows for maximum freedom of movement and optimal protection of the robot—even under extreme conditions. Trust in high-quality materials, state-of-the-art technology, and certified safety to protect your equipment and work cells.

We provide the right protective solution for every robot system. Our circular knit material made of polyamide/elastane is anti-static and free of grease and silicone. It flexibly adapts to every robot movement and provides excellent protection.

With painting robots, hose routing often complicates the use of protective covers. Our specialized tailoring solves this challenge with custom-fitted systems, for example, using resealable hook-and-loop fasteners. The result is a tailored solution for your requirements.

Other Applications

We also develop and implement state-of-the-art robotic solutions for a wide variety of surface treatment applications. These include flame treatment robots, specifically designed for flame-treating plastic components, as well as powerful systems for heavy-duty corrosion protection, such as sandblasting systems and metallizing equipment. The programming of these robotic systems follows a principle very similar to that of paint robots: First, the applicators are intensively tested and carefully optimized in a testing phase using specially prepared test pieces. Once all optimal settings and parameters have been precisely determined and established, they are integrated into the program and finalized.